1 Ton per hour feed mill plant

- Brand:Difengou

- Color:Customized

- Size:Large, Medium, Small

- Package:Container

- Service life:Over 20 years

Main Parameter of DFOP400 Small Feed Pellet Plant

| DFOP400 Small Feed Pellet Plant | |||||

|---|---|---|---|---|---|

| Production capacity(kg/h) | Polluting range (mm) | Pellet density(t/m3) | Total power(kw) | Working dimension(mm) | Pellet Machine Type |

| 800-1000 | Diameter: 2.5-6 | 0.6-1.2 | 41.31 | 1960×3500×3500 | flat die |

Note: The yield was measured using 6 mm die holes in raw materials of 65% corn, 20% oil cake, rice bran or bran 15%.

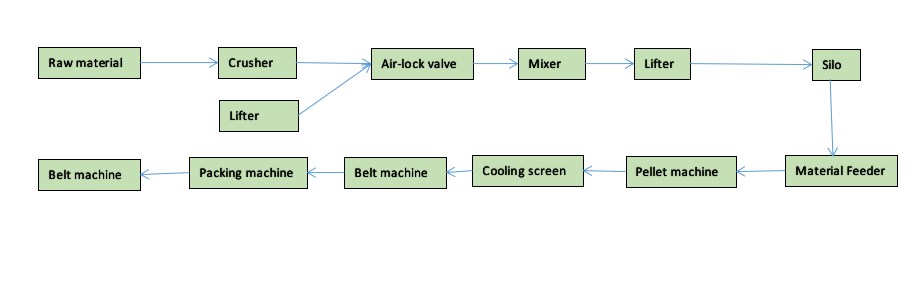

Poultry Feed Machine Technical Process

FSC500 Crusher

FSC500 type crusher, in combination with vertical mixing machine or horizontal mixing machine, used for crushing corn, soybean etc. widely suitable for small scale feed factory, animal farm etc.

This unit is featured with compact layout, advanced performance, small covering area, low electricity consumption, easy operation and repair, low noise and low pollution of dust.

| FSC500 Crusher for Pellet Line | ||||

|---|---|---|---|---|

| Production capacity(kg/h) | power(kw) | Crusher Diameter(mm) | Hammer qty(pc) | Overall dimension(mm) |

| 1000-1200 | 22 | 500 | 24 | 900×1000×1200 |

LS Series Screw Conveyor

The LS series screw conveyor consists of a feed hopper, a spiral blade, a motor reducer and a discharge port. Continuous conveying equipment that uses spiral rotation to move materials, this screw conveyor is suitable for conveying loose materials such as flour, grain, wood chips, cement, fertilizer, ash, sand, gravel, coal powder.

| No. | Type | Power (kw) | Conveying Capacity (t/h) | Overall Dimension (mm) |

|---|---|---|---|---|

| 1 | LS220*3.5 | 3 | 2-4 | 3500×500×300 |

| 2 | LS220*6 | 4 | 2-4 | 5900×500×300 |

TGFZ250 Airlock

The airlock is composed of an impeller, a casing, a motor reducer, etc., and is used for closed-air transportation of powder and granular materials.

| Feeding Yield(t/h) | Power(kw) | Overall Dimension(mm) |

|---|---|---|

| 2-4 | 0.75 | 810×295×395 |

9HWP500 Mixer

The 9HWP500 mixer is mainly composed of a motor, a reducer, a casing, a rotor and a discharge port, widely used in feed processing plants and farms as combined feed units and kinds of feed raw materials mixed according to the scale. The machine has the characteristics of simple structure, convenient maintenance, safety and reliability, high mixing uniformity, short mixing time and small residual amount.

| 9HWP500 Mixer Machine | |||

|---|---|---|---|

| Production Capacity() | Power(kw) | Mixing Time Foe Each batch(min) | Overall Dimension(mm) |

| 500 | 7.5 | 8-10 | 2940×920×2100 |

Silo and Feeder

The silo can store a batch of materials in the mixer to ensure continuous production of the entire production line. The silo is equipped with venting holes and venting bags to reduce dust spillage.

The feeder adopts the structure of the motor reducer, and the operation is stable. The feeder uses the frequency conversion speed regulation, which can accurately control the feeding amount of the pellet machine to ensure the smooth running of the pellet machine.

| Silo and Feeder | |||

|---|---|---|---|

| Production Capacity(m³) | Feeder motor power | Feeding speed(kg/h) | Overall Dimension(mm) |

| 1.5 | 0.75 | 100-1500 | 1800×1250×3350 |

ZLSG400 Fate Die Pellet Machine

ZLSG400 pellet machine consists of an inlet and outlet hopper, a press roll, a die plate, a coupling and a motor, used for producing dense feed pellets by pressing the feed material through a press roll and a die plate.

| ZLSG400 Fate Die Pellet Machine | |||

|---|---|---|---|

| Production Capacity(kg/h) | Power(kw) | Pelleting hole specification (mm) | Overall Dimension(mm) |

| 800-1000 | 30 | 2.5、3、4、5、6、8 | 1600×640×1300 |

LQSF70 Cooling Screen

The LQSF70 Cooling Screener is a special equipment for cooling and sorting particles, suitable for screening the kinds of feed, wood pellets etc, with the features of high screening efficiency, low noise, low dust emission, long service life, simple maintenance and simple operation etc.

| LQSF70 Drum Screening Machine | |||

|---|---|---|---|

| Production capacity (kg/h) | Power (kw) | Net/rough weight (kg) | Overall dimension (mm) |

| 400-600 | 0.75 | 200/245 | 1980*680*952 |

Bag –type dust collector is mainly used for the collection of debris and dust, collecting the broken dust and fines into the bag, reducing the dust density of the air, ensuring the working environment is celan.

| LQSF70 Bag-Type Dust Collector | ||||||

|---|---|---|---|---|---|---|

| Motor power (kw) | Rotary speed (r/min) | Sound (MMH20) | Flow (m/h) | Filtering Area (㎡) | Net/rough weight (kg) | Overall dimension (mm) |

| 2.2×2 | 2900 | 130 | 2280 | 4.2×2 | 100/135 | 1050*650*1150 |

QB380 Belt Conveyor

QB380 belt conveyor is used for conveying the finished pellets, adopting the belt with ribs and skirt, outputting with big dip, with large conveying quantity, covering a small area.

| Belt Conveyor | ||

|---|---|---|

| Power (Kw) | Conveying capacity (t/h) | Overall dimension (mm) |

| 2.2 | 2 | 5900×700×700 |

BZD50W Feed Pellet Packer

BZD50W packaging machine includes hopper, packaging machine, belt conveyor and sealing machine, etc. It is used for quantitative packaging of granular materials in feed, grain, fertilizer, rice, seed, chemical, food and other industries.

| BZD50W Feed Pellet Packer Machine | ||||

|---|---|---|---|---|

| Total power(Kw) | Packing specification (kg/per bag) | Packing speed (bag/h) | Packing accuracy | Overall dimension (not including conveying and sealing machine) (mm) |

| 1 | 0-50 | 180-220 | ≤±0.2% | 1000*1000*3500 |

Electric Control System

The electrical control of this small feed pellet plant is advanced and reliable. Each machine is all single-machine single control. When controlling the machine singly, the order should be used for starting: mixer— air lock machine —crusher—conveyor—belt machine—cooling screen—pellet machine—material feeding machine—packing machine.