- Customer Name:Breeder Free Range Chain Feeding System

- Status:In Process

- Date:2024-12

- Email:info@dfopoultry.com

- WhatsApp:0086 18638017260

- Share:

Project Details

One of the key techniques to enhance the production performance of breeding chickens is to improve flock uniformity.

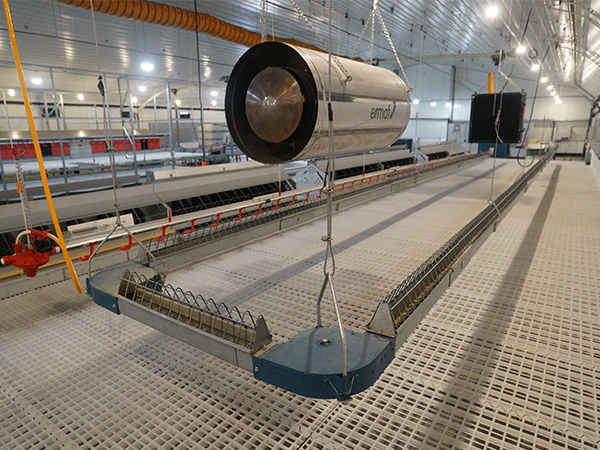

The breeder floor farming system has an automatic feeding system, automatic drinking system, egg collection system, manure cleaning system, lighting system, and ventilation system. These systems can be customized based on the farm’s specific conditions.

The above free-range farming equipment guarantees rapid feed distribution, improving breeding chickens’ uniformity. Ensuring that every breeding chicken in the flock consumes the same amount of feed within the same time frame

The speed of feed distribution determines the duration of the feeding process. Proper use of a chain feeding system ensures that feed is distributed to the troughs in the shortest possible time, thereby ensuring higher flock uniformity.

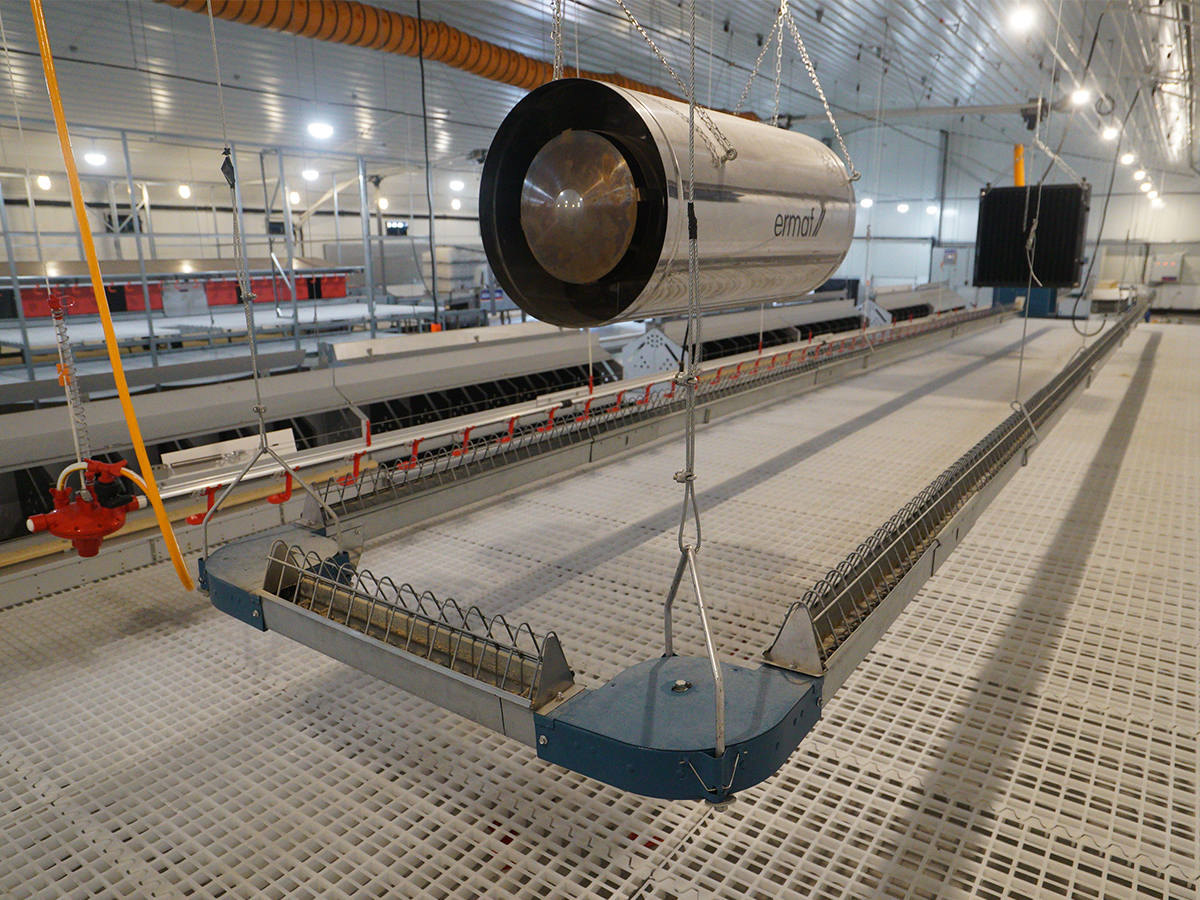

The breeder free-range chain feeding system consists of components such as a feed hopper, chain, motor, trough, corner wheels, and lift brackets. By activating the motor and pulling the chain, feed in the hopper is delivered to the trough. The chain feeding system is not only simple to operate, fast in feed delivery, uniform, and stable but also conserves feed, saves labor, and prevents feed contamination. By adjusting the feed outlet and pressing a button, clean feed can be quickly and evenly distributed into the trough. Additionally, the trough length is set according to the number of birds, ensuring scientifically reasonable feeding positions. This prevents crowding while avoiding excess trough space.

Chain Feeding System for Laying Hens Configuration Standards:

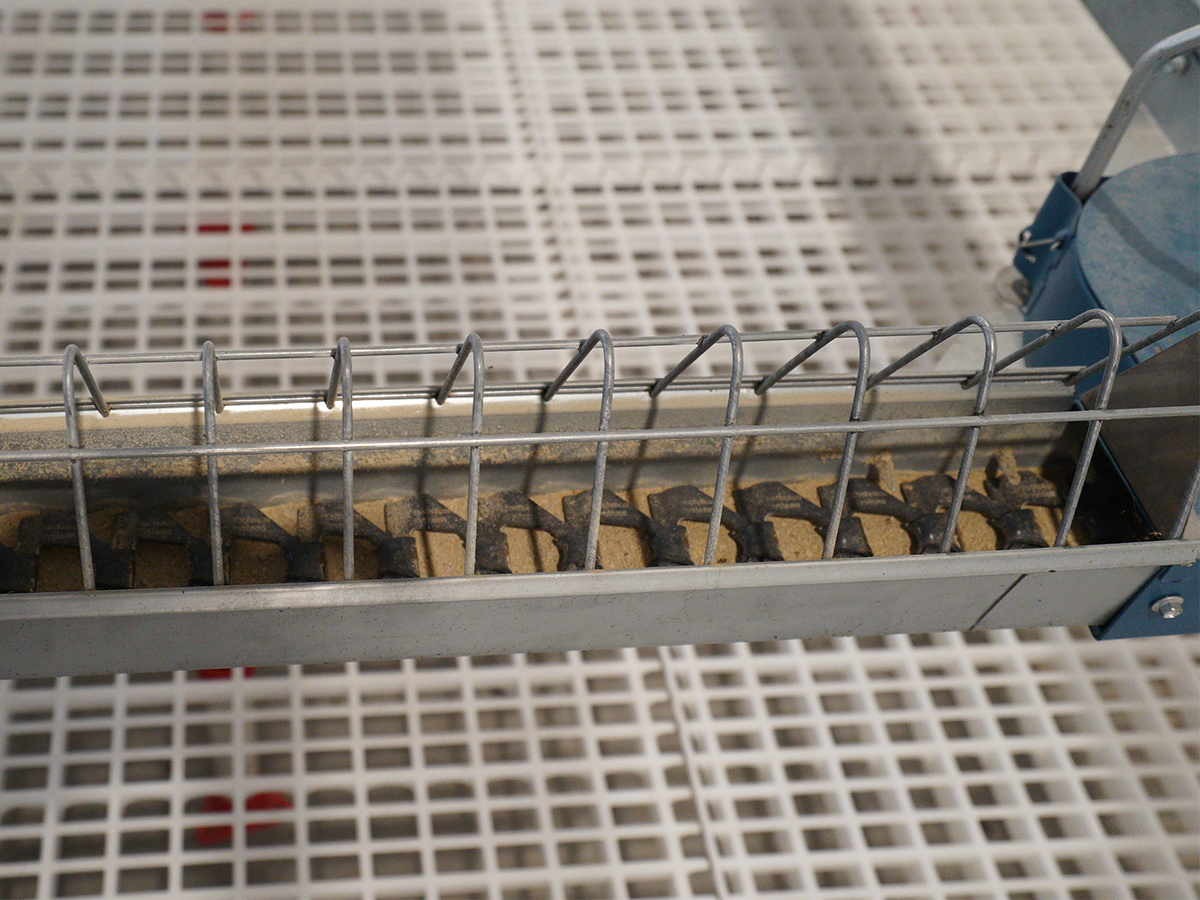

Trough:

Made from 275g hot-dip galvanized steel with CNC bending, the material thickness is not less than 1.2mm. Each trough is 3 meters long, with a feeding capacity of 12 hens per meter.

Feed Restriction Grids:

Equipped with hot-dip galvanized wire grids, each 1.5 meters long. The wire diameter is not less than 4.0mm, with feeding openings measuring 46mm × 65mm. Designed with double reinforcement ribs.

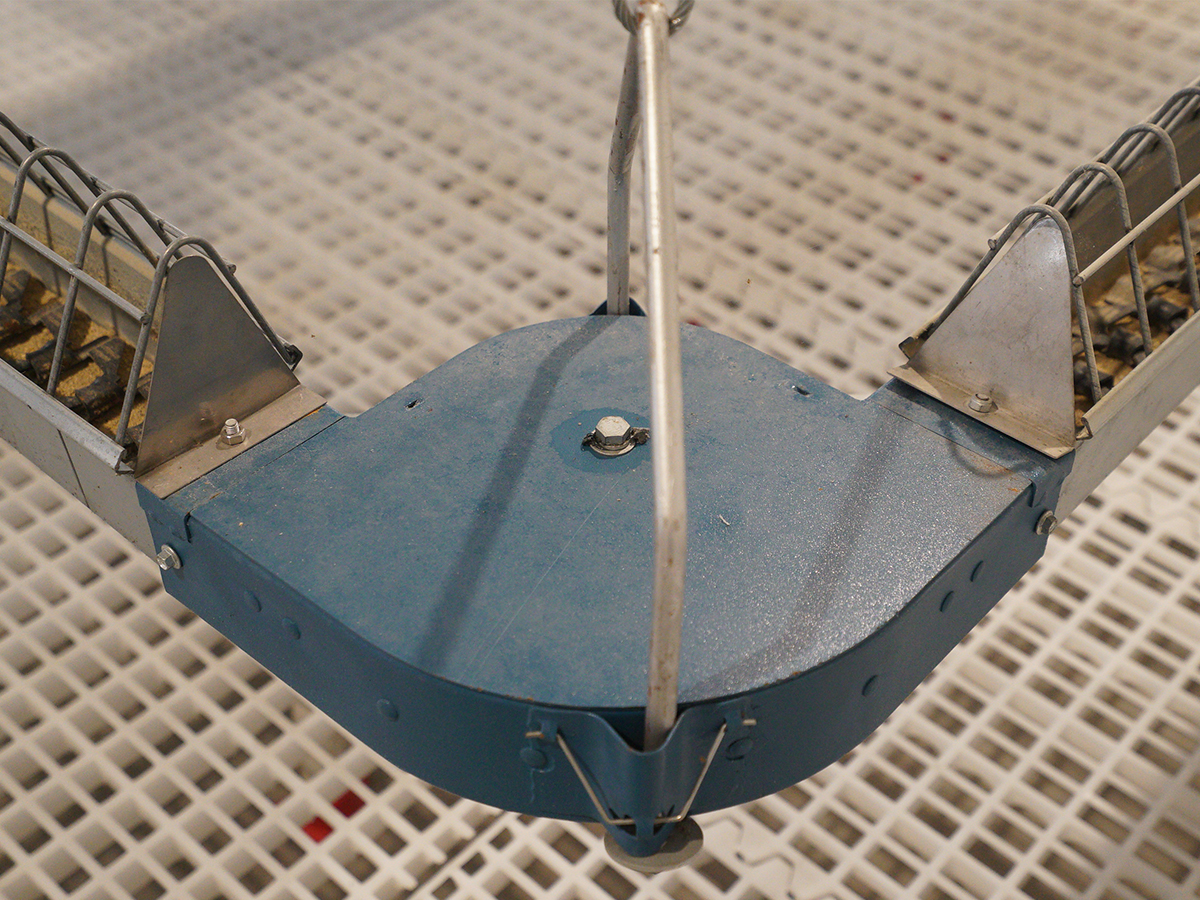

Trough Joints:

Made from 275g hot-dip galvanized steel with a material thickness of no less than 2.0mm.

Drive Units:

Each feed line is equipped with a branded drive unit, including base protection plates. The unit is tightly integrated with the gear and includes a perch prevention cover.

Feed Hoppers:

Each feed line is equipped with two large hoppers with a capacity of no less than 280kg. The hopper body is made of 275g hot-dip galvanized steel with a thickness of no less than 1.2mm, and adjustable legs with a thickness of no less than 2.0mm.

Corner Wheels:

Each feed line cycle is equipped with four corner wheels. The inner wheels are high-frequency quenched, designed with double bearings, offering strong tensile and wear resistance.

Control Panel:

The control panel uses branded electrical components and allows independent operation of each feed line.

Patent-Type Double-Bearing Corner Unit

High-Strength Alloy Wheel:

The corner wheel is made of a special high-strength alloy steel, featuring high hardness, wear resistance, and long service life.

Maintenance-Free Bearings:

The wheel shaft is equipped with high-strength, maintenance-free double bearings, ensuring simplicity and convenience.

Anti-Static Coating:

The outer shell of the corner unit is treated with an anti-static spray coating.

Feed Restriction End Cap:

Each corner unit is equipped with an end cap for feed restriction grids.

Durable Cast Steel Wheel:

The corner wheel is made of 45# cast steel and processed with quenching to achieve a hardness of HRC50-52, providing excellent wear resistance.

Compact Shaft Design:

The shaft is designed to minimize the entry of feed into the bearings, ensuring durability.

During the production phase, due to the need for mating, roosters should be housed with hens in the same pen but fed separately. This approach is highly beneficial for preventing leg disorders in roosters, improving fertilization rates and hatchability of hatching eggs, and reducing feed waste.

Starting from 20 weeks of age, mixed-sex housing is implemented with separate feeding systems for roosters and hens. Rooster feed is provided using male feed lines or feed buckets (8–10 roosters per bucket). The feed buckets should be suspended at a height of 41–46 cm from the ground, adjusted weekly according to the height of the roosters’ backs. The height should ensure that hens cannot reach the feed, while roosters can access it by standing on their toes.

Hen feeding systems include feed buckets or chain feeders equipped with anti-roosting grids. The grid spacing for parent stock hens should be 42.5–43 mm, allowing only hens to feed while preventing roosters from inserting their heads.

Rooster feed buckets must be stable and level to ensure consistent feed levels. During feeding, hens should be fed first, followed by roosters. Feed should be distributed quickly and evenly so that both roosters and hens can eat simultaneously, preventing roosters from wandering around in search of food.

Egg collection system

The breeder free-range egg collection system includes laying boxes and a conveyor belt, ensuring that eggs are automatically transported outside the chicken house, reducing the egg breakage rate, and decreasing labor requirements.