A type and H type layer battery cage for African market

A layer chicken cage is a kind of poultry cage, designed to confine the laying hens, enabling them to lay eggs in a controlled environment. This controlled confinement is convenient for poultry farmers as it serves the dual purpose of raising chickens and facilitating the collection of eggs. The primary goal of these cages is to optimize the conditions for egg-laying hens,when they reach the age of 12 to 16 weeks. It’s crucial to transfer them to the layer cage system ensuring their well-being while maximizing egg production.

In the modern poultry farming industry, battery cage has developed not only for layers but also for broilers, brooders (baby chicks), pullet. Difengou manufactures battery cages for layers, broilers, brooders, pullets with advanced machines. To meet different demands, the A type battery chicken cage and H type battery chicken cage are both supplied.

A Type Layer Cage

- The chicken cage type: A type layer cage

- Tiers: 3/4

- Capacity: 90-160birds/set

- Accessory: Automatic feeding machine, Drinking water system

- Material: Hot galvanized, cold galvanized (according to customers’ requirement)

- Application: Large scale layer farm

| A type layer cage technical parameter | |||||

| Model | Tier | Door | Birds/Cage (Pcs) | Space / Brids (Cm2) | Cage size (mm) |

| A-90 | 3 | 5 | 3 | 455 | 1950*350*380 |

| A-96 | 3 | 4 | 4 | 426.5 | |

| A-120 | 4 | 5 | 3 | 455 | |

| 4 | 5 | 4 | 448.5 | 1950*460*420 | |

| A-128 | 4 | 4 | 3 | 426.5 | 1950*350*380 |

| A-160 | 4 | 5 | 4 | 448.5 | 1950*460*420 |

H Type Layer Cage

- The chicken cage type: H type layer cage

- Tiers: 3-8 or more upon request

- Capacity: 54-288 birds/set

- Accessory: Automatic feeding machine, Drinking water system, Egg collecting machine

- Material: Hot galvanized

- Application: Large scale layer farm

| H type layer chicken battery cage specification | |||||

| Model | Tier | Door | Birds/Cage (Pcs) | Space / Brids (Cm2) | Cage size (mm) |

| H-96 | 3 | 2 | 8 | 96 | 1200*625*480 |

| H-128 | 4 | 2 | 8 | 128 | |

| H-160 | 5 | 2 | 9 | 160 | |

| H-192 | 6 | 2 | 9 | 192 | |

| H-224 | 7 | 2 | 9 | 224 | |

| H-256 | 8 | 2 | 9 | 256 | |

Layer Cage For Chicks

- The chicken cage type: A type & H type pullet cage

- Tiers: 3-4 tiers

- Material: Hot galvanized

- Application: chicks, poults

A leading layer battery cage supplier from China

Difengou Farming is one of the professional chicken battery cage system suppliers based in China. Our chicken battery cages are constructed from high quality hot galvanized steel ensuring robust and long-lasting performance. Which can expect a service life of up to 30 years .We specialize in providing complete sets of equipment tailored to the specific needs of your poultry farm. Difengou offers expert guidance and support, helping you make the most of our equipment and optimize your poultry production. ensuring that your farm operates efficiently and profitably.

- Subject: Poultry farming solutions

- Chicken Cage: Layer cage, Battery cage, Brooder Cage

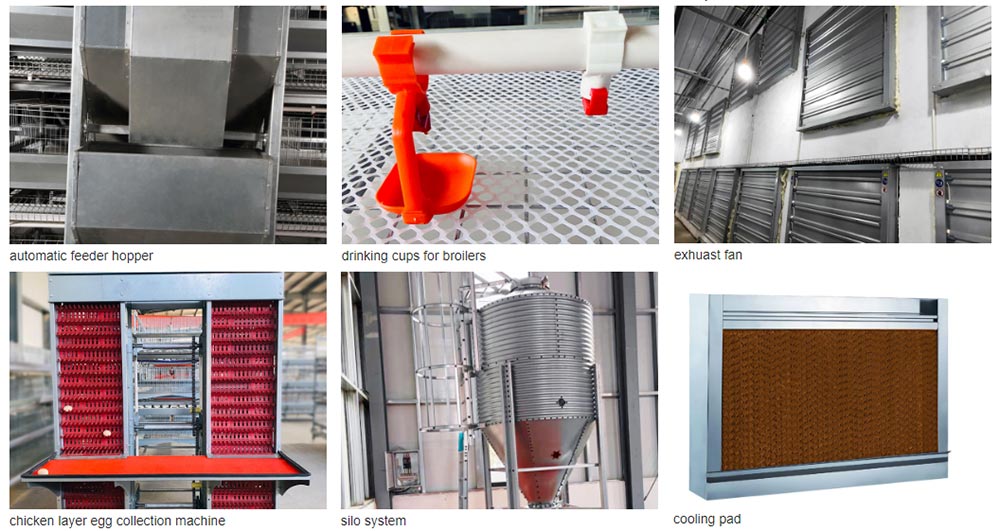

- Equipment: Pellet Feed Mill, Poultry incubator, Egg grading machine, Solar cold room, Manure dewatering machine, feed grinders and mixers (On demand selection)

- Application: Laying hens, broilers, chicks

How to selecting the Right Chicken Farming Equipment for your farm ?

Choosing the appropriate poultry farming equipment depends on your flock’s size and specific needs. Here’s a quick guide:

Less than 2,000 Layer Chickens:

For smaller flocks, could use manual battery cage.

Drinking systems can be automated, but feeding, egg collection, and waste removal require manually operated.

5,000 to 10,000 Chickens:

Invest in a manure removal machine and poultry battery cages.

Timely waste removal improves chicken health and egg production.

Semi-automatic feeding machines are cost-effective.

Over 10,000 Layer Chickens:

Opt for fully automatic equipment:

Battery cages, automatic feeders, drinking system, egg collectors, and manure removal systems.

Suitable for larger operations, providing efficiency and labor savings.

Scale Beyond 50,000 Chickens:

You could use fully automatic system with environmental Control:

Closed houses with exhaust fans and cooling pads.create a controlled, disease-free, and comfortable environment that is conducive to high egg production, better egg quality, and more efficient poultry management.

Please feel free to contact directly. Let us know your specific requirements, such as the number of chickens you intend to raise, whether you already have a chicken house in place, or the dimensions of your poultry facility. Our team will provide a personalized and cost-effective solution that meets your unique needs.

Get In Touch Now!

Leave messages for quotations and solutions. The average response time is with in 24 hours.Your privacy is protected.